substrates steel

Color | Grey |

Mixing ratio (weight) | 25: 3 Stir well with mechanical stirring |

Specific gravity (after mixing) | 2.30±0.1kg/L |

Bulk solids | 60±3% |

Typical dry film thickness | 80um |

Typical wet film thickness | 135um |

Theoretical coating rate | 0.307kg/m²/80um |

Surface stem | ≤1h |

Practical | ≤24h |

Fully cured | 7d |

Mixed use period | ≤4h(23℃±2) |

Diluent | Epoxy diluent |

Applicable | , cast iron, etc |

Front-end coating | — |

Back-end coating | Epoxy micaceous iron intermediate paint |

Product Introduction

It is composed of epoxy resin, modified polyamide curing agent, ultra-fine zinc powder, additives and solvents. The metal zinc content in the dry film reaches more than 70%, which has excellent cathodic protection effect, and can provide long-term anti-corrosion protection for the coated object when used with epoxy coating, and the paint film is tough and dense, excellent damp and heat resistance, long-term corrosion resistance in the marine environment, and has excellent adhesion to the metal substrate

Product Use:

The surface of steel equipment suitable for bridges, towers, petroleum, smelting, chemical and other industries in the harsh corrosive environment of industrial environment is used as the most basic anti-rust primer, and is used as a protective primer after shot blasting or sandblasting of steel plates

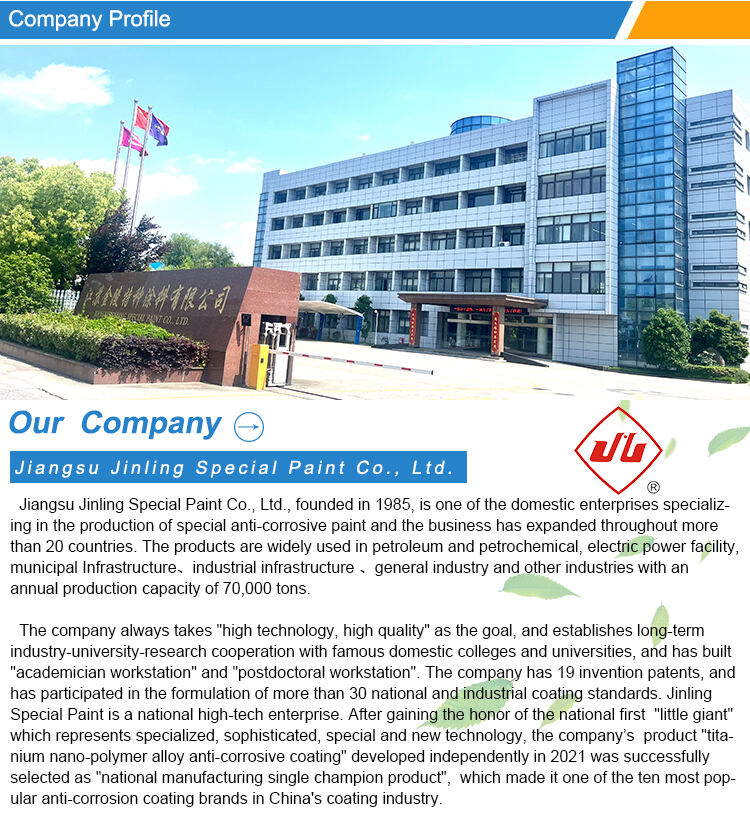

Q1 Are you a manufacturer and support factory site visits?

A: We are a professional paint manufacturer with more than 30 years of experience and support buyers to visit our factory.

Q2 What are your main products?

A: Our main products are all kinds of industrial anti-corrosion coatings, marine coatings, floor coatings, new water-based

environmental protection coatings, automotive coatings and so on.

Q3 Is the coating product sold by your company in compliance with the relevant entry permit for each country?

A: All types of coating products produced by our company are in compliance with international relevant quality standards and requirements. For some countries, there are special access certification licenses. Our company will conduct targeted product verification.

Q4 Does your company still need an international agent to join?

A: To meet the requirements of customers, we welcome you to become our agent dealer, become our agent dealers will receive more favorable prices and account period support, specific operation details please contact our company account manager to confirm

JINLING PAINT

If you’re looking for a high-quality outdoor metal anti-corrosion primer to protect your valuable steel equipment, then you need to check out Epoxy Zinc Rich Primer.

Made to provide maximum corrosion protection for metal equipment is used in outdoor surroundings. The JINLING PAINT formula is exclusive a higher amount of zinc, which acts as a sacrificial anode, preventing the steel from corroding. This means your gear shall keep going longer, function better, and need less upkeep in the long run.

Incredibly versatile. It can be utilized on a selection of steel areas that need protection from corrosion. This primer is to get the job done right whether you’re working with industrial gear, pipeline structures, offshore platforms.

One of the key advantages is its capability to adhere to steel areas. Which means that it won’t peel, break, or flake off over time, making sure your gear remains protected for a long time to come. The primer can be resistant to abrasion and impact, so it will endure the toughest conditions and that means you can be.

In addition to its excellent characteristics protective, this is simple to apply. It could be sprayed, brushed, or rolled onto the surface of one's equipment, it dries quickly, enabling you to go onto the stage is next of project right away. Plus, it’s obtainable in a variety of colors, in order to pick the shade is perfect match your equipment.

with JINLING PAINT’s reputation for quality and reliability, you can be sure that you’re getting an Epoxy Zinc Rich Primer that will deliver the results you need.

EN

EN

AR

AR BG

BG HR

HR RO

RO RU

RU ES

ES TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ TR

TR MS

MS HY

HY AZ

AZ KA

KA BN

BN BS

BS GU

GU LO

LO LA

LA MN

MN NE

NE YO

YO MY

MY KK

KK UZ

UZ AM

AM KU

KU KY

KY