Color | Grey |

Mixing ratio (weight) | 25: 3 Stir well with mechanical stirring |

Specific gravity (after mixing) | 2.1±0.1kg/L |

Bulk solids | 58±3% |

Typical dry film thickness | 80um |

Typical wet film thickness | 138um |

Theoretical coating rate | 0.290kg/m²/80um |

Surface stem | ≤1h |

Practical | ≤24h |

Fully cured | 7d |

Mixed use period | ≤4h (23℃±2) |

Diluent | Epoxy diluent |

Applicable substrates | Steel, cast iron, etc |

Front-end coating | — |

Back-end coating | Epoxy micaceous iron intermediate paint |

Product Introduction

It is composed of epoxy resin, modified polyamide curing agent, ultra-fine zinc powder, additives and solvents. The metal zinc content in the dry film reaches more than 60%, which has excellent cathodic protection, and can provide long-term anti-corrosion protection for the coated object when used in conjunction with epoxy coatings.

Product Use:

The surface of steel equipment suitable for bridges, towers, petroleum, smelting, chemical and other industries in the harsh corrosive environment of industrial environment is used as the most basic anti-rust primer, and is used as a protective primer after shot blasting or sandblasting of steel plates

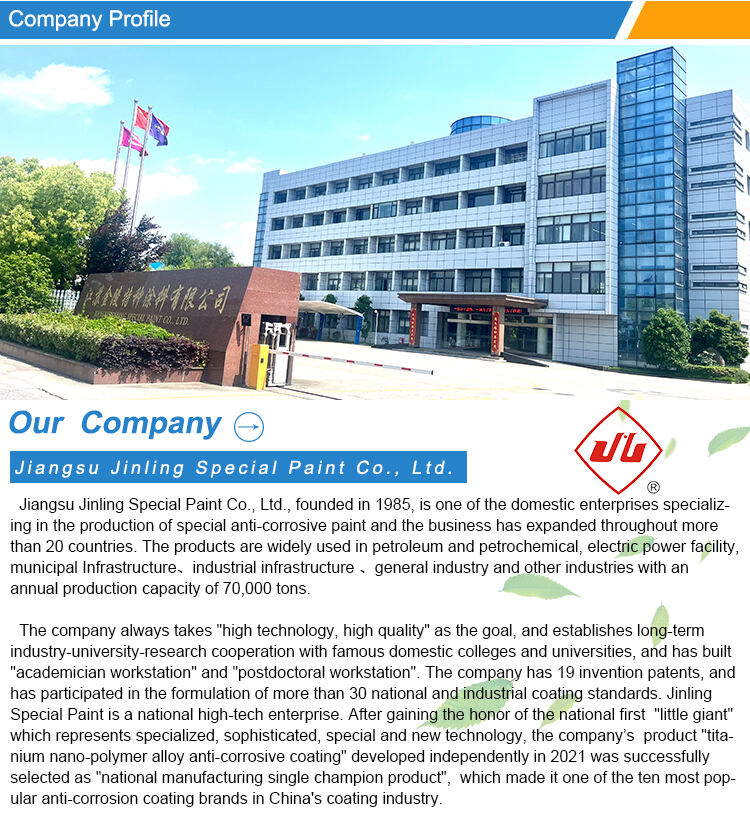

Q1 Are you a manufacturer and support factory site visits?

A: We are a professional paint manufacturer with more than 30 years of experience and support buyers to visit our factory.

Q2 What are your main products?

A: Our main products are all kinds of industrial anti-corrosion coatings, marine coatings, floor coatings, new water-based

environmental protection coatings, automotive coatings and so on.

Q3 Is the coating product sold by your company in compliance with the relevant entry permit for each country?

A: All types of coating products produced by our company are in compliance with international relevant quality standards and requirements. For some countries, there are special access certification licenses. Our company will conduct targeted product verification.

Q4 Does your company still need an international agent to join?

A: To meet the requirements of customers, we welcome you to become our agent dealer, become our agent dealers will receive more favorable prices and account period support, specific operation details please contact our company account manager to confirm

JINLING PAINT carries to you their most current item in steel framework security - the Manufacturing facility Epoxy Anti-Corrosion Recoat. This top quality Recoat is particularly developed for technical devices and jobs marvels to avoid rust and corrosion.

Created along with zinc-rich epoxy, this Recoat is the supreme service for safeguarding steel frameworks coming from issues trigger with moisture, major comfortable and make it through.

Great for utilize in manufacturing focuses that are susceptible to corrosion. Not simply performs it deal security is remarkable rust nonetheless it likewise broadens the life expectancy of gadgets. This is since the Recoat is developed to endure create it with is major, producing it invulnerable to abrasion, fading, and damaging.

Easy to utilize and demands little location preparation function previous to need. It can be place on each new and steels being developed and dries rapidly to deal an also degree and soft. It is perfect for use on technical gadgets, considerable devices, and steel frameworks subjected to major atmospheres.

Created to be extremely adaptable, to ensure that it fits the advancement is typical contraction of steels. This will create it perfect for gadgets is subjected to temperature level is higher and also copied shocks.

Furthermore it is invulnerable to chemicals, that produces it effectively appropriate for utilize in manufacturing focuses that perform handling is chemical. Is provided in an option of shades, enabling you to choose the mood that fits your also devices and brand. It is versatile, extremely simple to cleanse, and might be correctly utilized for each interior and needs which can be outdoors. The product will be provided in a 5-liter drum and also an area is 20-liter according to your requirements.

EN

EN

AR

AR BG

BG HR

HR RO

RO RU

RU ES

ES TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ TR

TR MS

MS HY

HY AZ

AZ KA

KA BN

BN BS

BS GU

GU LO

LO LA

LA MN

MN NE

NE YO

YO MY

MY KK

KK UZ

UZ AM

AM KU

KU KY

KY