রঙ | ধূসর |

মিশ্রণ অনুপাত (ওজন) | 25: 3 মেশিনিক্যালি মিশিয়ে ভালভাবে মেশান |

বিশেষ গুরুত্ব (মিশানোর পর) | 2.1±0.1kg/L |

গ্রাহক ঠক্কর | 58±3% |

টাইপিক্যাল শুকনো ফিল্মের মোটা | 80মিক্রোমিটার |

টাইপিক্যাল ঘন ফিল্মের মোটা | 138um |

তত্ত্বগত কোটিংग হার | 0.290kg/m²/80um |

পৃষ্ঠ দণ্ড | ≤1h |

বাস্তব | ≤24ঘন্টা |

সম্পূর্ণভাবে শুকনো | 7দিন |

মিশ্রণ ব্যবহারের সময় | ≤৪ঘন্টা (২৩℃±২) |

diluent | এপক্সি ডিলিউটেন্ট |

যোগ্য বহুমাত্রিক | আইরন, লোহা ইত্যাদি |

প্রথম আবরণ | — |

শেষ আবরণ | এপক্সি মাইক্রোস্কোপিক আয়রন ইন্টারমিডিএট পেইন্ট |

পণ্য পরিচিতি

এটি এপক্সি রেজিন, পরিবর্তিত পলিঅ্যামাইড ফিক্সিং এজেন্ট, অতি-সূক্ষ্ম জিংক পাউডার, যোগাযোগ এবং দ্রাবক দ্বারা গঠিত। শুকনো ফিল্মে ধাতব জিংকের পরিমাণ ৬০% বেশি হয়, যা উত্তম ক্যাথোডিক সুরক্ষা প্রদান করে এবং এপক্সি কোটিং সঙ্গে ব্যবহার করলে কোটিংযুক্ত বস্তুর দীর্ঘমেয়াদী নিরোগীকরণ সুরক্ষা প্রদান করতে পারে

পণ্য ব্যবহার:

পুল, টাওয়ার, তেল, সংশ্লেষণ, রসায়ন এবং অন্যান্য শিল্পের কঠোর করোসিভ পরিবেশে লোহার যন্ত্রপাতির পৃষ্ঠে এটি সবচেয়ে মৌলিক রংধনু প্রাইমার হিসেবে ব্যবহৃত হয় এবং শট ব্লাস্টিং বা স্যান্ড ব্লাস্টিং পরে লোহার চালের প্রোটেকটিভ প্রাইমার হিসেবে ব্যবহৃত হয়।

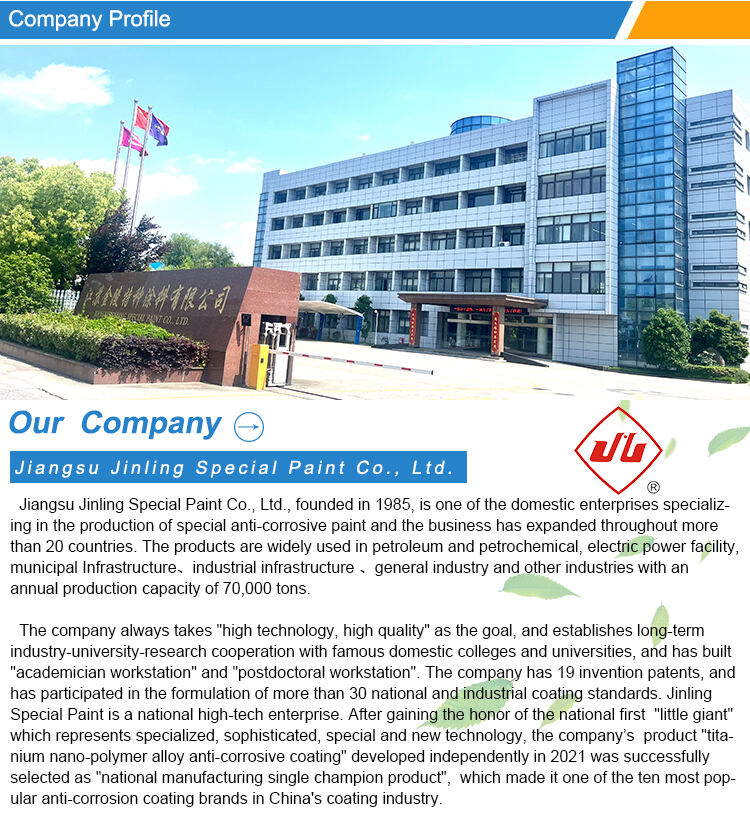

প্রশ্ন ১: কি আপনি একজন প্রস্তুতকারক এবং কারখানা ভ্রমণ সমর্থন করেন?

আমরা ৩০ বছরের অধিক অভিজ্ঞতা সহ একটি পেইন্ট নির্মাতা এবং আমরা ক্রেতাদের আমাদের ফ্যাক্টরিতে ভিজিট করতে সহায়তা করি।

প্রশ্ন ২: আপনাদের প্রধান উৎপাদনগুলো কি?

উত্তর: আমাদের প্রধান উৎপাদনগুলো বিভিন্ন ধরনের শিল্পি ঘৃণা ও রক্ষণশীল কোটিং, সमুদ্রী কোটিং, ফ্লোর কোটিং, নতুন জল-ভিত্তিক

পরিবেশ সুরক্ষা কোটিং, গাড়ির কোটিং ইত্যাদি।

প্রশ্ন ৩: আপনাদের কোম্পানি বিক্রি করা কোটিং পণ্য কি প্রতিটি দেশের জন্য সংশ্লিষ্ট প্রবেশ অনুমতির সাথে মেলে?

উত্তর: আমাদের কোম্পানি যে সকল ধরনের কোটিং পণ্য উৎপাদিত করে তা আন্তর্জাতিক সংশ্লিষ্ট গুণবত্তা মানদণ্ড এবং আবশ্যকতার সাথে মেলে। কিছু দেশের জন্য বিশেষ প্রবেশ সনদ লাইসেন্স আছে। আমাদের কোম্পানি লক্ষ্যমুখী পণ্য যাচাই করবে।

প্রশ্ন ৪: আপনাদের কোম্পানি আরও আন্তর্জাতিক এজেন্ট যোগদানের প্রয়োজন হয় কি?

আ: গ্রাহকদের প্রয়োজন মেটাতে, আমরা আপনাকে আমাদের এজেন্ট ডিলার হতে অভ্যর্থনা জানাই। আমাদের এজেন্ট ডিলার হলে আপনি বেশি সুবিধাজনক মূল্য এবং হিসাব সময়ের সমর্থন পাবেন। বিশেষ চালু বিবরণ জানতে আমাদের কোম্পানির অ্যাকাউন্ট ম্যানেজারের সাথে যোগাযোগ করুন।

JINLING PAINT

যদি আপনি একটি শিল্প অ্যান্টি-কোরোসিভ লেপ জন্য বাজারে হয় উভয় টেকসই এবং নির্ভরযোগ্য, তারপর Epoxy দস্তা সমৃদ্ধ প্রাইমার (60%) HX-066 চেয়ে আর খুঁজুন না। এই দুই উপাদান ধূসর ইপোক্সি জিংক সমৃদ্ধ প্রাইমার ভারী দায়িত্ব অ্যাপ্লিকেশন জন্য নিখুঁত, জারা এবং অবনতি বিরুদ্ধে ব্যতিক্রমী সুরক্ষা প্রদান।

অন্যান্য লেপগুলির বিপরীতে যা JINLING PAINT দীর্ঘমেয়াদে পচা বা মরিচা হয়ে যায়, এটি পরিবেশের জন্য কঠিন অবস্থার প্রতিরোধের জন্য তৈরি করা হয়েছে। এর উচ্চ জিংক উপাদানের অর্থ হল এটি আপনার ইস্পাত অংশের উপরে ক্ষয় প্রতিরোধী পণ্যের একটি শক্তিশালী স্তর টাইপ করে, এমনকি সবচেয়ে চরম অবস্থার মধ্যেও দীর্ঘস্থায়ী ক্ষয় থেকে সুরক্ষা প্রদান করে।

এর অন্যতম বড় প্রতিভা হল এর নমনীয়তা। এটি ইস্পাত, লোহা, অ্যালুমিনিয়াম, তামা, ধাতু এবং আরও অনেক কিছু সহ বিস্তৃত ক্ষেত্রে ব্যবহারের জন্য উপযুক্ত। এটি একটি ব্রাশ, রোলার বা স্প্রে বন্দুক ব্যবহার করা যেতে পারে, এটি ব্যবহারকারী-বান্ধব করে তোলে, অনেকের জন্য যারা ব্যাপক বাণিজ্যিক লেপগুলির অভিজ্ঞতা নাও থাকতে পারে।

আরেকটি বড় সুবিধা হল এটিতে কম ভিওসি থাকে, যার মানে এটিতে পরিবেশ এবং মানুষের স্বাস্থ্যের জন্য ক্ষতিকারক কম রাসায়নিক থাকে। এটি একটি পরিবেশ বান্ধব পছন্দ করে তোলে যা বিশ্বব্যাপী নিরাপত্তা এবং টেকসইতার প্রয়োজনীয়তা মেনে চলে।

শিল্প বিশেষজ্ঞদের দ্বারা পরীক্ষা করা এবং প্রত্যয়িত করা হয়েছে যাতে এটি সমস্ত উপযুক্ত মানের মান পূরণ করে। এটি অন্যান্য ধরনের লেপগুলির তুলনায় দীর্ঘস্থায়ী বলে প্রমাণিত হয়েছে, যা এটিকে একটি সাশ্রয়ী মূল্যের এবং ব্যয়বহুল বিকল্প করে তোলে যা কোম্পানিগুলি তাদের ধাতব এলাকাগুলিকে খুব দীর্ঘ সময়ের জন্য রক্ষা করতে চায়।

JINLING PAINT-এর Epoxy Zinc-Rich Primer (60%) HX-066 ব্যবহার করে আপনি নিশ্চিত থাকতে পারেন যে আপনার ধাতব পৃষ্ঠগুলি অসংখ্য উত্তাপ, জলবায়ু এবং অন্যান্য ধরনের ক্ষতি থেকে প্রতিরক্ষা পাবে আসন্ন বছরগুলিতে।

EN

EN

AR

AR BG

BG HR

HR RO

RO RU

RU ES

ES TL

TL IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK VI

VI SQ

SQ TR

TR MS

MS HY

HY AZ

AZ KA

KA BN

BN BS

BS GU

GU LO

LO LA

LA MN

MN NE

NE YO

YO MY

MY KK

KK UZ

UZ AM

AM KU

KU KY

KY